Billet-specialties FM 0105PC SBC Manuel d'utilisateur

Naviguer en ligne ou télécharger Manuel d'utilisateur pour Pour la voiture Billet-specialties FM 0105PC SBC. Billet Specialties FM 0105PC SBC User Manual [en] Manuel d'utilisatio

- Page / 1

- Table des matières

- MARQUE LIVRES

Noté. / 5. Basé sur avis des utilisateurs

Billet Specialties, Inc. 500 Shawmut Avenue La Grange, Illinois 60526 PH 800.245.5382 Fax 708.588.7181 www.billetspecialties.com

We recommend applying Anti-Seize to all threads when assembling bracket.

1) Disconnect Battery

2) Clean and prep engine block for installation. Inspect threads in engine block, Run a 3/8” thread

chaser if necessary. Thread chasers are available at your local auto parts store or tool dealer and are

different from a thread cutting tap.

3) Loosely assemble alternator bracket by inserting the (2) 3/8-16 x 3” socket head cap screws

through front bracket. Place 1-7/8” spacer on top bolt. Place in order on bottom bolt 1-3/32” spacer,

turn buckle assembly then 5/16” spacer. Thread completed assembly through rear bracket and into

engine block. Do not tighten at this time

4) Attach small aluminum ear bracket to back of alternator mount boss with(1) 5/16-18 x 7/8” socket

head cap screw and tighten (26 ft./lb.)

5) Place alternator between front and rear brackets, thread (1) 3/8-16 x 2-3/4” socket head cap screw

through front bracket, alternator and into rear bracket. Finger tighten.

6) Swing turnbuckle assembly up to aluminum ear bracket and thread (1) 3/8-16 x 1” socket head cap

screw through turnbuckle and into aluminum ear bracket and tighten (46 ft./lb.)

7) Tighten the (2) 3/8-16 x 3” socket head cap screws into engine block at this time. (46 ft./lb.)

8) Route V-Belt over water pump pulley, crank pulley and alternator pulley. Turn turnbuckle until

proper belt tension is achieved. Tighten jam nuts on turn buckle. Tighten alternator socket head cap

screw at this time. (46 ft./lb.) Re-check belt tension.

9) Reconnect electrical and test run motor. Re-check belt tension after 100 miles.

Tools Required:

1/4” Allen Wrench

5/16” Allen wrench

1/2” Open End Wrench

9/16” Open End Wrench

Anti-Seize

3/8-16 Thread Chaser (If necessary)

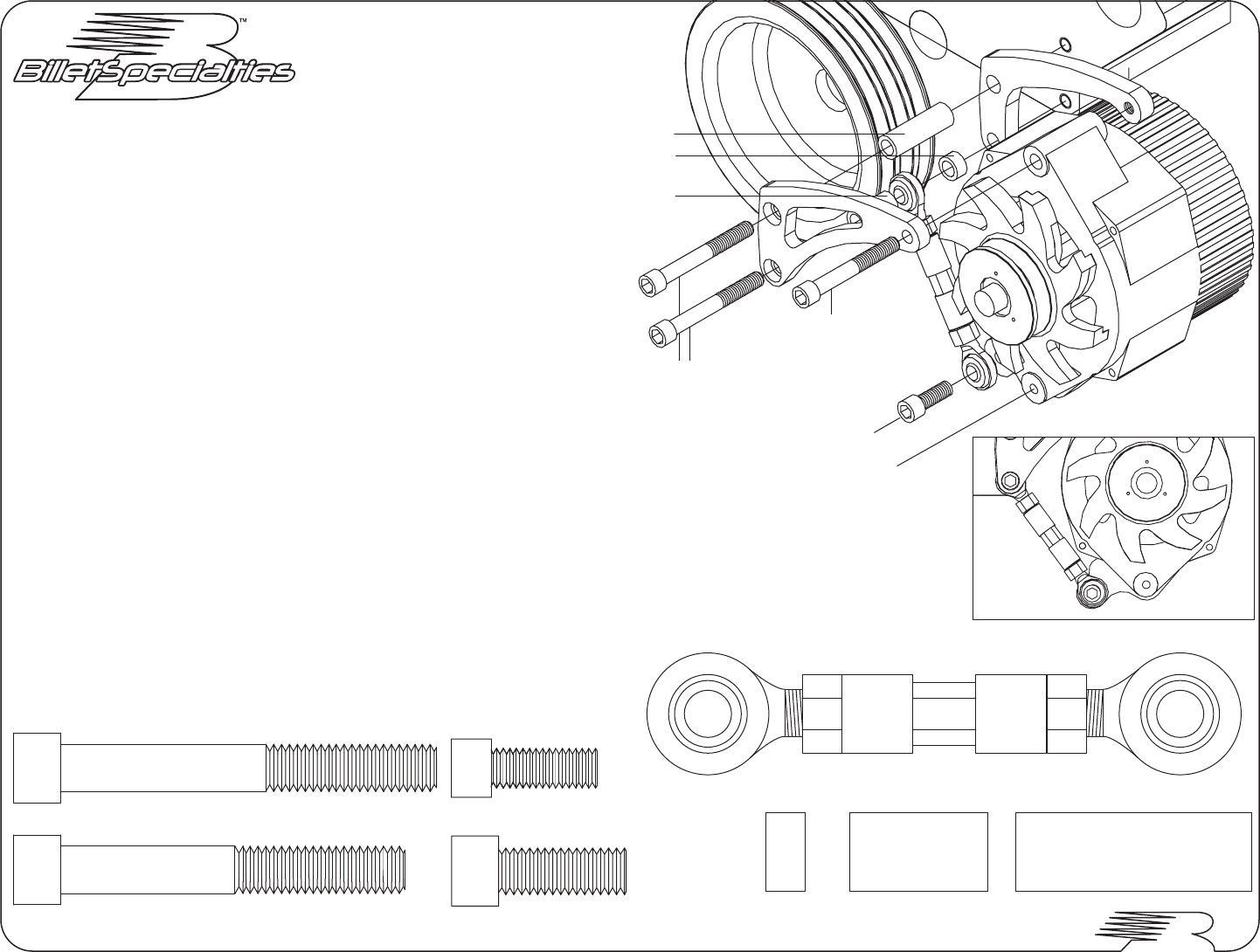

FM 0105PC SBC low mount alternator Bracket

5/16" Spacer

1-3/32" Spacer

1-7/8" Spacer

3/8-16 x 1" S.H.C.S.

Bolts To Ear Bracket

3/8"-16 x 2-3/4" S.H.C.S.

3/8"-16 x 3" S.H.C.S.

5/16-18 x 7/8" Socket Head

Cap Screw From Behind

5/16" Spacer 1-3/32" Spacer

Turnbuckle Assembly

1-7/8" Spacer

(2) 3/8-16 x 3" Socket Head Cap Screw

(1) 3/8-16 x 1" Socket Head Cap Screw(1) 3/8-16 x 2-3/4" Socket Head Cap Screw

(1) 5/16-18 x 7/8" Socket Head Cap Screw

1

Résumé du contenu

Page 1

Billet Specialties, Inc. 500 Shawmut Avenue La Grange, Illinois 60526 PH 800.245.5382 Fax 708.588.7181 www.billetspecialties.comWe

(1 pages)

(1 pages)

Commentaires sur ces manuels